Cerakote has even lasted better than a pistol I had a Ion Bond finish on. So if you have, say, nickel plating on your gun (not sure why you would), Cerakote probably would not work. Cerakote is a ceramic finish that can be applied only to the substrate material (fancy word for the material that is to be covered). Corrosion resistance will depend on the exact way the coating is applied, but it's usually similar to hard chrome, not impervious but much better than bluing and if kept oiled will likely never be a problem. Click check permissions then click 0755 or 0777 to see if that works (or do it. The downside is that it is more expensive than Cerakote or Melonite (More on that in a sec). It may pick up marks but that's from softer materials abrading and getting stuck to the finish. I suppose you could sand through it using silicon carbide sandpaper but short of that not much is going to hurt it. The ceramic is harder and more wear resistant than any other coating, to damage it requires hitting it hard enough to damage the steel under the coating or specific chemicals (hydrogen peroxide for hair bleaching damaged the gold titanium nitride finish that Bodycote used on high end sink faucets). It might show some chips or handling wear but most of the gun will have great corrosion. Cerakote over park or Anodizing would make a great finish for a hard use gun that will be exposed to the elements for a long period of time due to its corrosion resistance. Ionbond is an ultra-hard (harder than any steel) coating applied and bonded to the steel, most PVD coatings like this are done via plasma sputtering, not sure if ionbond is using a different technology but the end result is a layer of micron thin ceramic material directly welded to the steel surface of the part. You should pick the finish based on its intended use. Solid Curved or Straight Match Grade Trigger-Standard. I found a black law folding adapter for a good price but its black and I need fde. I understand that it is my responsibility to have a valid FFL copy or any. The test begins now: Just 12 days into the test, the traditionally blued rifle begins to show signs of corrosion, while the Cerakote rifle shows no signs of corrosion. Well honestly its no contest ion bond wins but here is my situation. As long as it's not scratched to bare metal the finish is practically impervious to corrosion. The rifle on the right of the screen has been factory finished with Cerakote ceramic coating protection, while the rifle on the left has a traditional factory blued finish.

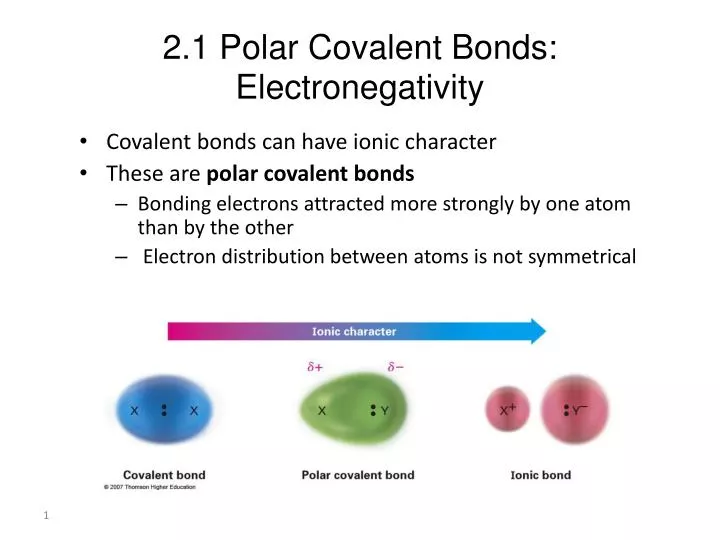

They're also unaffected by any gun cleaning product and only the most powerful paint strippers have a chance of softening them, most off the shelf paint strippers (kleen strip, citri-strip) won't do anything to them. They are softer than steel brushes but you shouldn't be using those anyways. These types of resin based coatings are usually hard enough to resist damage from things like bronze and brass cleaning brushes when applied correctly. The two main types of chemical bonds are ionic and covalent bonds. Cerakote is a ceramic particle infused resin coating, the ceramic is a lubricating type rather than abrasive type of ceramic, most likely boron nitride in micron powder form.

0 kommentar(er)

0 kommentar(er)